PRODUCTION

I am XINTAI – I know what quality means. And the first condition of my manufacturing products is that they are developed according to the (brake discs) standards of the original products.

My priority is making sure all the parts I offer are of the highest quality. This is imperative to ensure safety and to live up to the Auger standard that promotes reliability. In order to ensure hands-on supervision of design and production, I have a team of highly qualified engineers, inspectors and workers.

CASTING

I has 4 sets of 3 Tons electric furnaces that can operate at the same time, which can complete the supply of 12 Tons of molten iron per hour, and the daily output is>150 Tons; The automatic sand mixer has 80T/per hour automatic sand mixing equipment,stable sand treatment, control of air permeability and compactness, to provide guarantee for the product.

MACHINING

I has two fully automated robotic machining lines to cope with the stringent requirements of the global market for commercial vehicle brake discs(brake rotors). Meanwhile, we have 20 CNC lathe production lines, which can guarantee a daily processing capacity of about 15,000 pieces of passenger car brake discs(brake rotors). The company has its own intellectual property rights of spraying production line, which can ensure the customer's various requirements for brake disc(brake rotors) surface coating.

WAREHOUSE & TRANSIT WORKSHOP

I has 8,000 square meters of digitally managed own warehouses and trans-shipment workshops, which facilitate the management of semi-finished and finished products, ensuring that goods flow accurately through the company and further guaranteeing delivery times to customers worldwide.

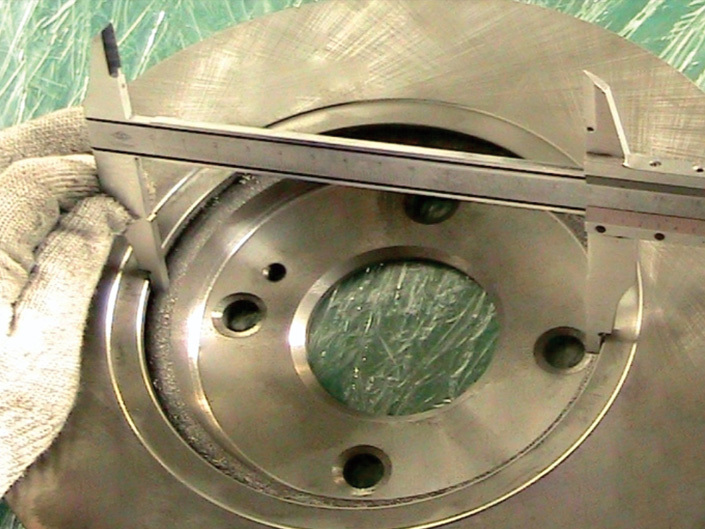

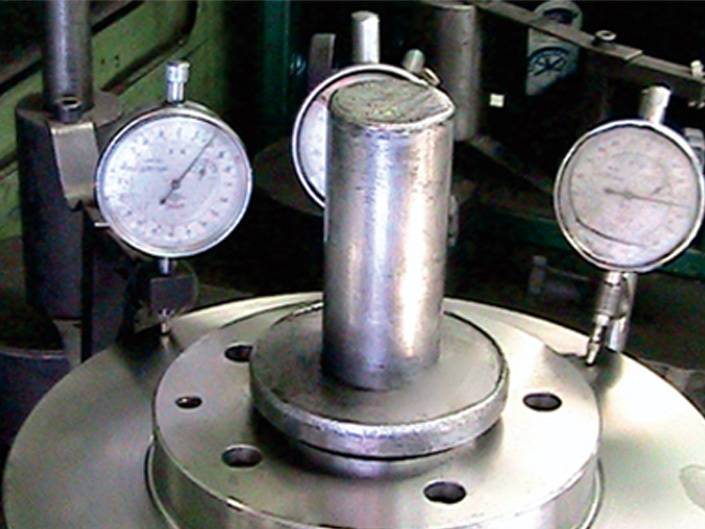

QUALITY CONTROL

In the foundry, I have direct reading spectrometers and carbon and sulfur analyzers to ensure the quality of the iron in each furnace. In the machining shop, I use the first piece inspection, On-Site inspection and final inspection to verify the assembly size of the brake discs(brake rotors). In the laboratory, I use hardness tester, tensile tester and metallographic analysis to ensure the material requirements of brake discs(brake rotors).

Contact

Tel:

+86 535 5923977

Cellphone:

+86 132 5699 5555

E-Mail:

Wangrs@plxintai.com(G.M. )

jiao@plxintai.com(Sales Director)